We are proud of our range of products for surface preparation prior to powder coating and would like to share the extremely satisfying results of our salt chamber tests. In this blog post, we will focus on technical aspects and details that may be of interest to paint line professionals.

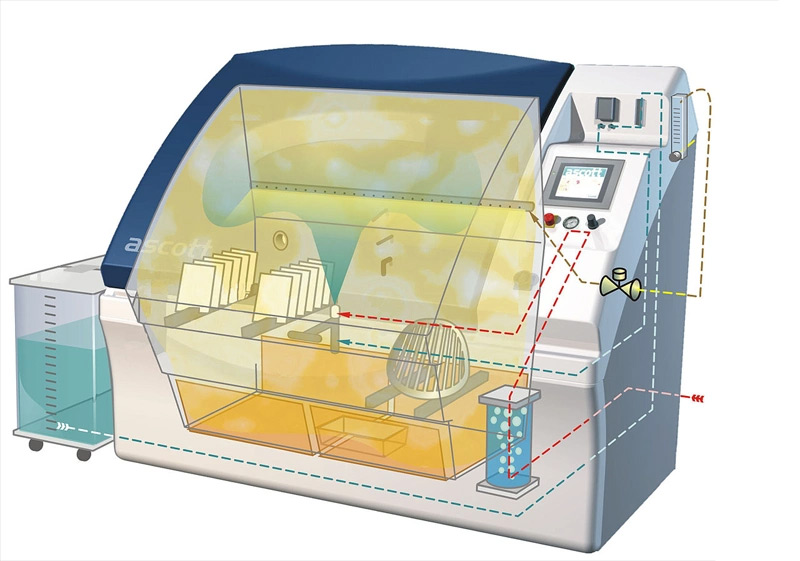

To start with - what is a salt chamber and what is the NSS test?

The NSS test, or Neutral Salt Spray test, is the standard method for testing the corrosion resistance of materials and surface coatings. This test is commonly used to check the corrosion resistance of metallic materials, although it can also be used to test ceramics and polymers. It involves testing coatings applied to the surface of a material to provide corrosion protection.

The inert salt spray test is a type of accelerated corrosion test that produces corrosion products on coated test samples. It is used to evaluate or compare the effectiveness of a given coating as corrosion protection. The presence of corrosion products, such as rust or oxides, is assessed after a specified period of time, which depends on the corrosion resistance of the coating.

Tests

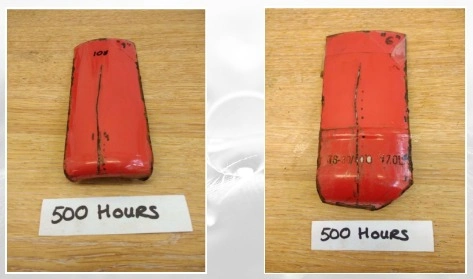

Our company had the pleasure of working with a client who had very exacting requirements for the durability of the paint finish. The salt chamber time requirement for the extinguishers was 450 hours, but the client made it clear that they expected a minimum of 500 hours of durability. We approached the job with full commitment and applied the Kairos chemistrywhich has been successfully working on many paint lines for a long time.

The results we achieved exceeded our wildest expectations. After surface preparation with Kairos chemistry, the paint coatings withstood more than 700 hours of salt chamber testing. This is undoubtedly a spectacular success and proof of the excellent surface preparation and confirmation of the quality of our products.

Summary

What makes the resulting paint finishes so extremely durable? The secret lies in the unique conversion coating, which provides high corrosion protection while at the same time energy savings compared to the traditional phosphatising process.

Our assistance is not limited to the provision of high-quality products. We are ready to support any company during the implementation phase of Kairos products. Our experts will analyse the needs of a large, medium or small paint line, make detailed calculations, and determine the optimal operating parameters. If necessary, we will carry out corrosion tests in a salt chamber. Our aim is to increase the durability and resistance of powder-coated products.

If you are interested in implementing our solutions in your company, we invite you to contact.